-

Milosava Vlajića 116e, Sopot, Serbia

Milosava Vlajića 116e, Sopot, Serbia

Concrete block splitters

Concrete block splitters

Concrete block splitters

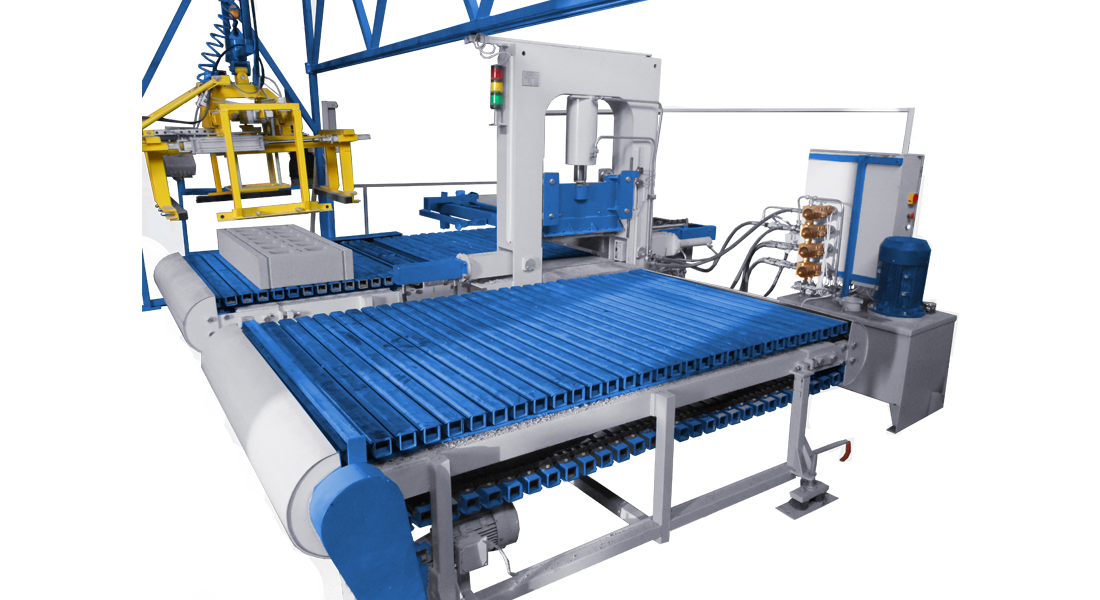

METALIKA designed automatic equipment, complete automatic line for concrete block splitting.

S-610-4-A is automatic line for splitting blocks and cubing station, on request cubing station can be automatic or semi-automatic

Block splitter can split all 4 sides of the block.

Technical data of concrete block splitter

Equipment

Different configurations your advantage on the market

Copyright 2025. Metalika. All Right Reserved.