-

Milosava Vlajića 116e, Sopot, Serbia

Milosava Vlajića 116e, Sopot, Serbia

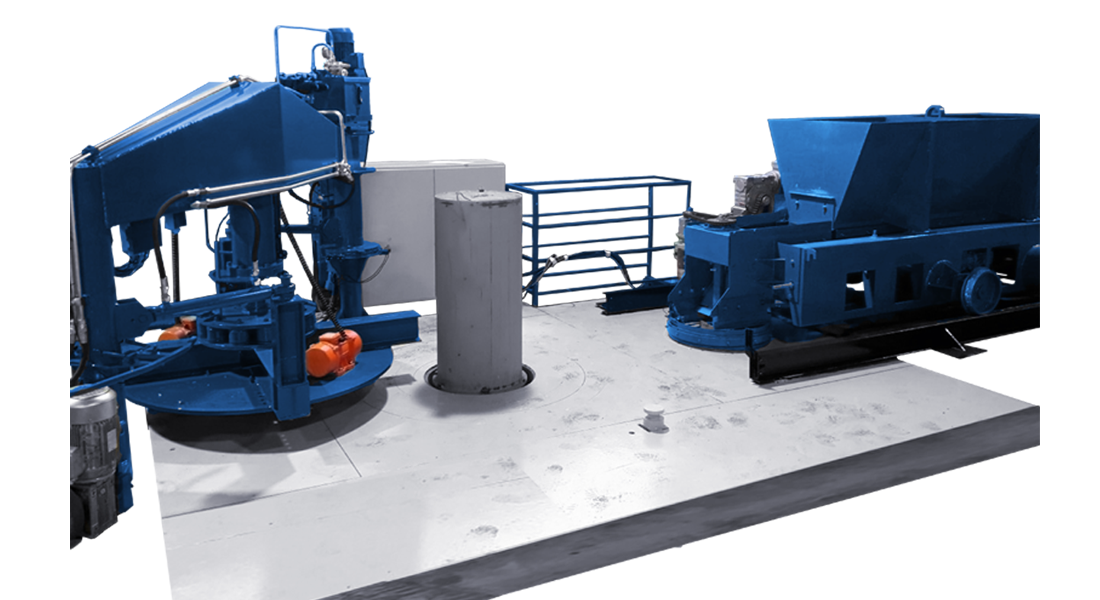

Concrete pipe making machine

Concrete pipe making machine

Concrete pipe making machine

C-1200 Concrete pipe machine produces concrete pipes diameter from 300-1200mm by vibrating of core.

Equipment for manufacturing concrete pipes is placed in concrete base built according to manufacturer’s layout.

Forming head for concrete pipes, electric and hydraulic controls are placed above surface.

Filling mold with concrete is performed with automatic concrete feeder unit or by belt conveyor from concrete mixer, depend on configuration of concrete pipe manufacturing line.

All operations are semi-automatic or automatic, depend on equipment configuration.

Wet concrete pipes are driven manually away with special cart or by chain conveyor, depend on equipment configuration.

All capacities are calculated as maximum – 100% efficiency for 8 hours of operation. When calculating the real production capacities, it is necessary to take into account the actual efficiency factor, which is approximately 80%, due to other factors that can affect productivity, such as: concrete (recipe of concrete), effective work of workers (with breaks), delivery of concrete in vibropress, concrete product design, mold features, production pallet-pad features, settings on the vibropress.

Different configurations your advantage on the market

Copyright 2025. Metalika. All Right Reserved.